How Much Oil Production Gain Can You Count on Gas-Lift Optimisation to Deliver?

How Much Oil Production Gain Can You Count on Gas-Lift Optimisation to Deliver?

Thierry Wee, 21st Aug 2021

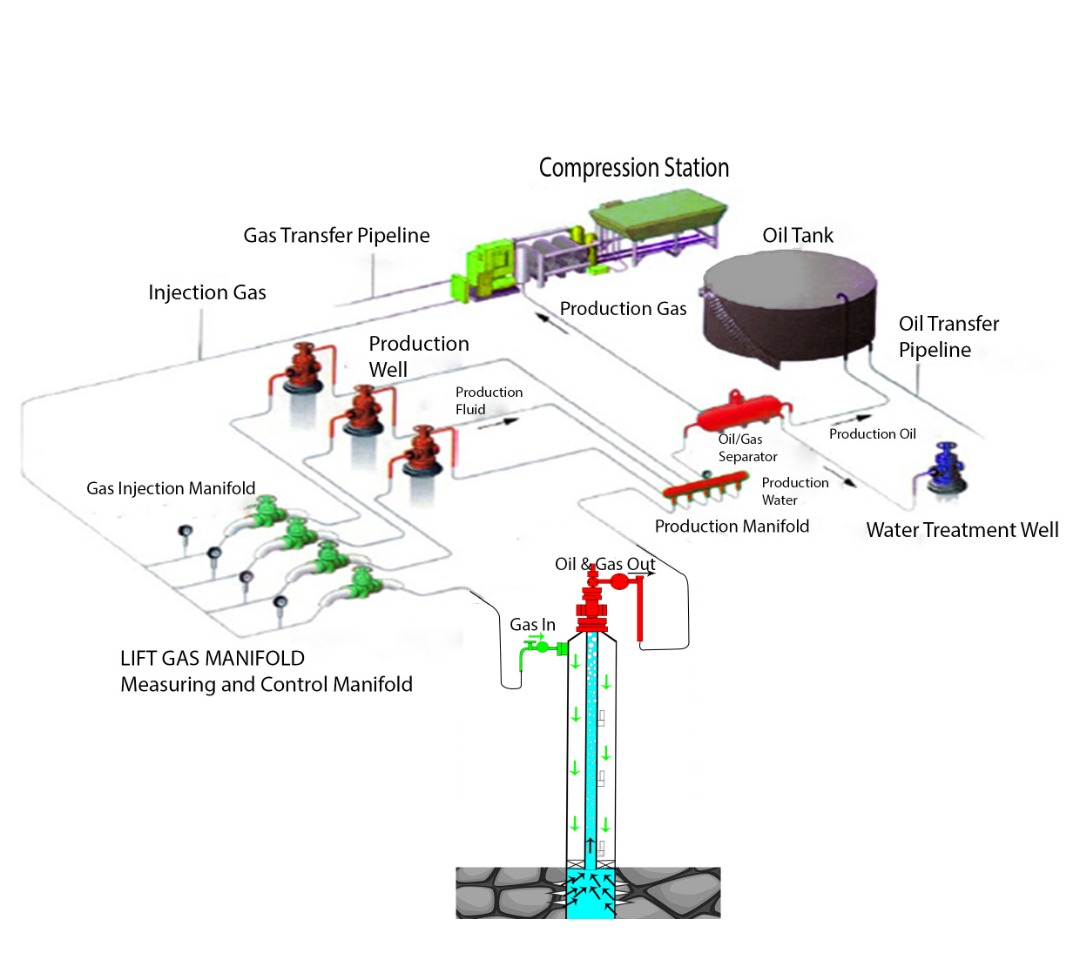

Gas-Lift is an artificial lift method for improving oil production in oil wells. The concept is relatively simple. By injecting a small amount of high-pressure gas (lift-gas or gas-lift) into the bottom of the well, this gas will lift the oil as it tries to travel up the well. Figure 1 shows a schematic of a gas-lift system. Many of us, who have worked in the oil field for many years, would have come across this artificial lift method for boosting oil production from a well. While many engineers swear by gas-lift to be the number one artificial lift method to go for when an oil company is looking for a “quick gain”, there are also those who have experienced poor results from gas-lift.

Figure 1: Gas-Lift System

Oil Gain from Gas-Lift

So, the question is. How much production gain can we expect from gas-lift or gas-lift optimisation? To answer this, we have carried out secondary research to provide relevant statistics, which mainly involved analysing published technical articles from the Society of Petroleum. We looked at 191 SPE papers published between 2018 to 2020 and followed through the various authors’ accounts of the use of gas-lift and the eventual results achieved across 41 countries in offshore and onshore oil fields. Many of the articles gave a fascinating story of the journey taken to implement gas-lift in the oil field. However, in this pursuit, we ask the question - “what is the oil gain attributed by gas-lift?”. Disappointedly, the number of useful articles which cited tangible oil gain figures quickly drop down to just a handful. We compiled the documented oil gain from the seven SPE papers (see Table 1) from gas-lift across 480+ wells.

Table 1: SPE Article/Paper

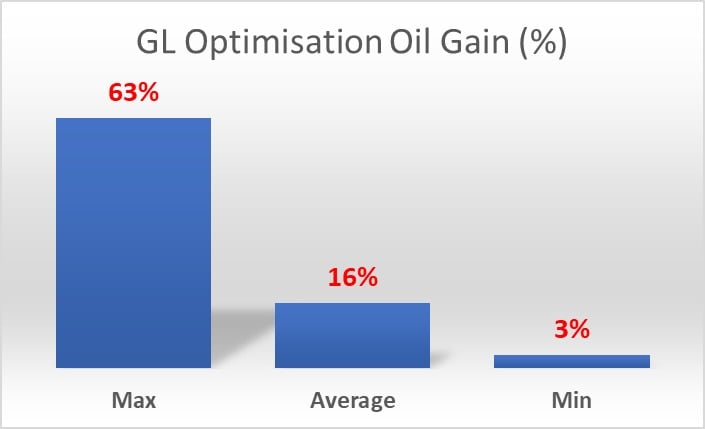

On average, gas-lift can give an oil gain of 16% (See Figure 2). However, in some cases, the oil gain can be as low as 3% while as high as 63% in other cases.

Figure 2: Gas-Lift Optimisation Oil Gain

What Is Ultimately Required for Gas-Lift To Be At Its Best?

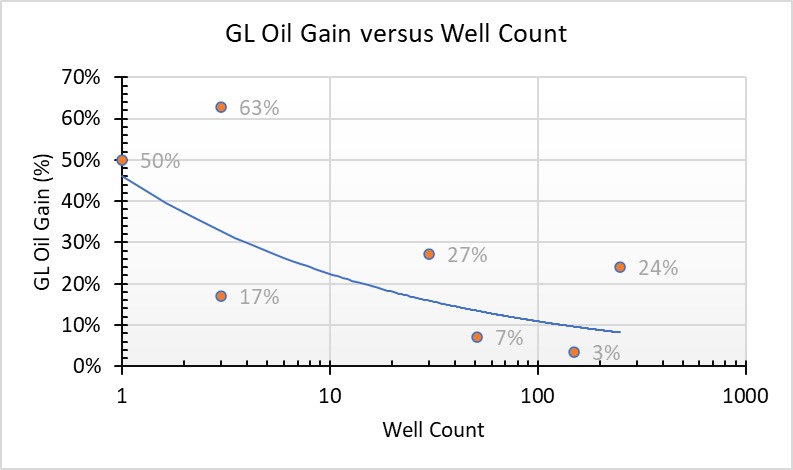

We asked ourselves why is there such a big spread between the highest and lowest data point. To answer this, we looked further into other aspects such as the geo-location, technology, field production age and well count. At first inspection, we found the circumstances of gas-lift application in each field are unique. Each field has its reasons for selecting the technology, the approach to the problem, the set of challenges, and the explanation of the achievement from gas-lift. To cut it short, it was impossible to establish a strong prediction of the result of one field to another field. However, when we looked at the data trend of oil gain versus well count, we can see a data trend begins to emerge – oil gain gets lower with an increasing number of wells (see Figure 3). For a moment, this phenomenon looks very similar to the law of diminishing returns or diminishing marginal productivity. In a simple explanation, when all other factors (such as human and equipment resources) are held constant, the work productivity initially increases with the number of tasks to be done up to a point where it is highest before it starts to drop.

A plausible example would be an engineer having to perform gas-lift optimisation for a small number of wells. As more wells are added to the plate, the engineer eventually reaches a saturation point. There are only so many wells he can look after before the quality and attention given starts to fall off.

Figure 3: Gas-Lift Oil Gain versus Well Count

So, we hypothesise the following hypothesis to explain the data trend:

“Gas-lift optimisation requires resources to happen.”

When only a smaller number of wells are selected for gas-lift optimisation, the finite company resources (such as gas-lift engineer, capital and equipment) will likely have a better chance to focus and perform better to give a better yield in the end. Imagine one (1) gas-lift engineer in charge of one (1) well versus one (1) gas-lift engineer in charge of one hundred (100) wells. It is easy to imagine the formal will likely give better results. We envisage that there is another aspect to be at play too for this to be true. At the start of the gas-lift project, the project team could have undergone a “cherry-picking” process to select the best well candidates to benefit from gas-lift from a larger well group. This upfront selection process can explain why a higher oil gain is sometimes observed for a gas-lift project done for a smaller number of wells. However, this is not to say that a higher oil gain is impossible for a more significant number of well counts. We believe that when implementing gas-lift optimisation across a larger number of wells, an equivalent larger amount of gas-lift engineer and technology resources is required to ensure the oil gain result will be as high as possible.

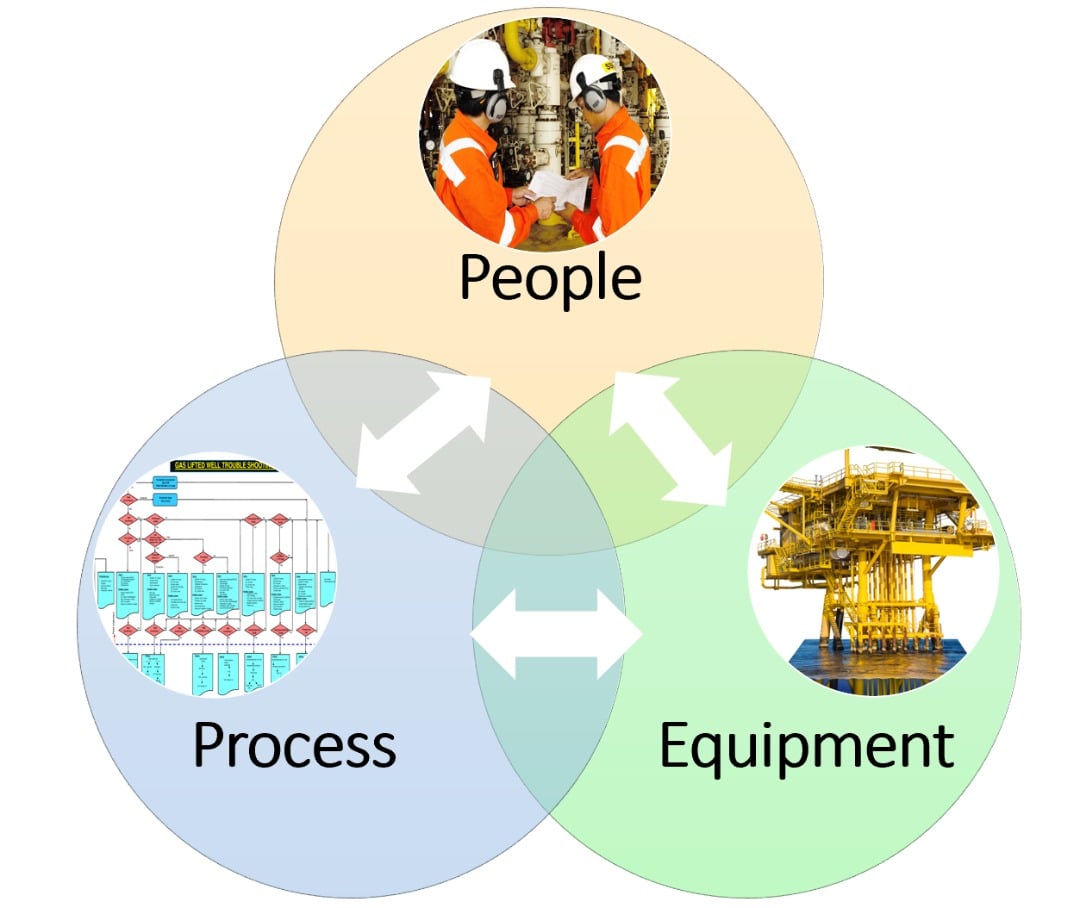

So, when one is looking to implement gas-lift for many wells, it might be a good idea to invest some time to work out if the plan has considered the following (see Figure 4):

- the correct number of gas-lift engineers

- the right technology

- he right strategy and the right processes

It might also be worthwhile to consider getting external resources to provide the expertise and experience if the in-house resource is already stretched.

Figure 4: Three Key Components to Gas-Lift Optimisation

Which One Is More Important for Oil Gain – Topside or Downhole?

When we looked at the nature of the gas-lift optimisation carried out for the various cases in Figure 1, we broadly differentiate the scope to either topside or downhole dominant. However, we understand that this might not be the most accurate way to do this. In this situation, we were aiming to make a high-level qualitative analysis of the situation. From the data, we found that, whether the gas-lift effort is topside or downhole focused, the results can be just as equally good or less than average. One explanation for this could be both the topside system and downhole system are intrinsically connected. Imagine a topside gas-lift supply network (consisting of a compressor and gas-lift pipelines) supplying lift-gas to many oil wells. At any one time, the operating condition of the topside gas-lift system can affect the operating condition of the downhole gas-lift equipment inside the wells. Hence, we conclude that it is equally important to focus on both the topside and the downhole when implementing gas-lift optimisation.

Other Benefits

One could also be surprised to learn that there is more to increasing oil production regarding gas-lift optimisation. It is common to expect oil wells to produce more oil production after implementing gas-lift optimisation. However, there are two sides to the coin. There are two scenarios: (1) the oil well has too little gas to reach optimum lifting performance, and (2) the oil well has too much lift-gas inside the well. The formal scenario gives more oil production after implementing gas-lift optimisation. Meanwhile, the latter scenario will give lift-gas savings after implementing gas-lift optimisation. Wan et al. (2018) and Wee et al. (2008) cited that about 25% of lift-gas consumption was saved in their gas-lift projects while maintaining the same oil production. The gas-saving also means less fuel burning for the running of the gas-lift compressor, which ultimately can give a longer running life to the compressor equipment and cut down the emission of greenhouse gas (GHG) to the environment. It is also possible that the lift-gas that was saved can further be used to inject more gas-lift in other needy wells to give further oil production.

In Conclusion

Gas-lift optimisation can yield significant oil gain when there are the right amount of human and technology resources, the right technology is selected, and the right strategy and process are used. It is essential to review and ensure that the project has put in more resources to yield above average results when implementing gas-lift for an extensive network of oil wells. Both the topside facilities system and downhole well system are equally important when implementing gas-lift optimisation.

References

Wee, T., Turco, A., McIlroy, R., de Boer, F., Cramer, R., Dolan, M. (2008) SPE-120461-MS: Brunei Shell Petroleum Champion Field Gas-Lift Optimization Project – FieldWare Production Universe Implementation in a Brown Field. Society of Petroleum Engineers.

Hord, T., Johnson, M. (2014) Global Gas Lift Optimization Using WellTracer Surveys. 37th Gas-Lift Workshop Houston, Texas, USA February 3 – 7, 2014. ASME International Petroleum Technology Institute.

Obong, B., Franklyn, O., Tima, E., Azibapu, F. (2018) SPE-193413-MS: The Use of Clamp-On Gas Flowmeter In Gas Lift Operations – Badan Field Experience. Society of Petroleum Engineers.

Wan-Khairul-nuar, W., Badawy, K., Abu-Bakar, K., Mohd-Aznam, M., Salahuddin, S., Mail, M., Abu-Bakar, A., Trivedi, R., Tri, N. (2018) SPE-191994: Integrated Operations for Gas Lift Optimization: A Successful Story at Peninsular Malaysia Field. Society of Petroleum Engineers.

Aoun, A., Maougal, F., Kabour, L., Liao, T., AbdallahElhadj, B., Behaz, S. (2018) SPE-1191542-MS: Hydrate Mitigation and Flare Reduction Using Intermittent Gas Lift in Hassi Messaoud, Algeria. Society of Petroleum Engineers.

Fouad-Sayed, R., Mohamed-Hashim, S., Shahin, E., Abd-Elmaksoud, M. (2020) OTC-30610-MS: Effective Use of Real-Time Remote Monitoring System in Offshore Oil Wells Optimization, Case Study from Gulf of Suez – July Field. Society of Petroleum Engineers.

Ulyanov, V., Neft, G., Kuchurin, A., Kibirev, E., Gryzunov, A., Bak, V., Rymarenko, K., Nukhaev, M., Dadakin, N. (2018) SPE-191533-18RPTC-MS: Implementation of the Intellectual Gas Control System for Gas Lift Optimization at Orenburgskoe Oilfield. Society of Petroleum Engineers.

If you would like to get in touch with Thierry to discuss this subject further, please contact him at thierry.wee@invigour-energy.com.